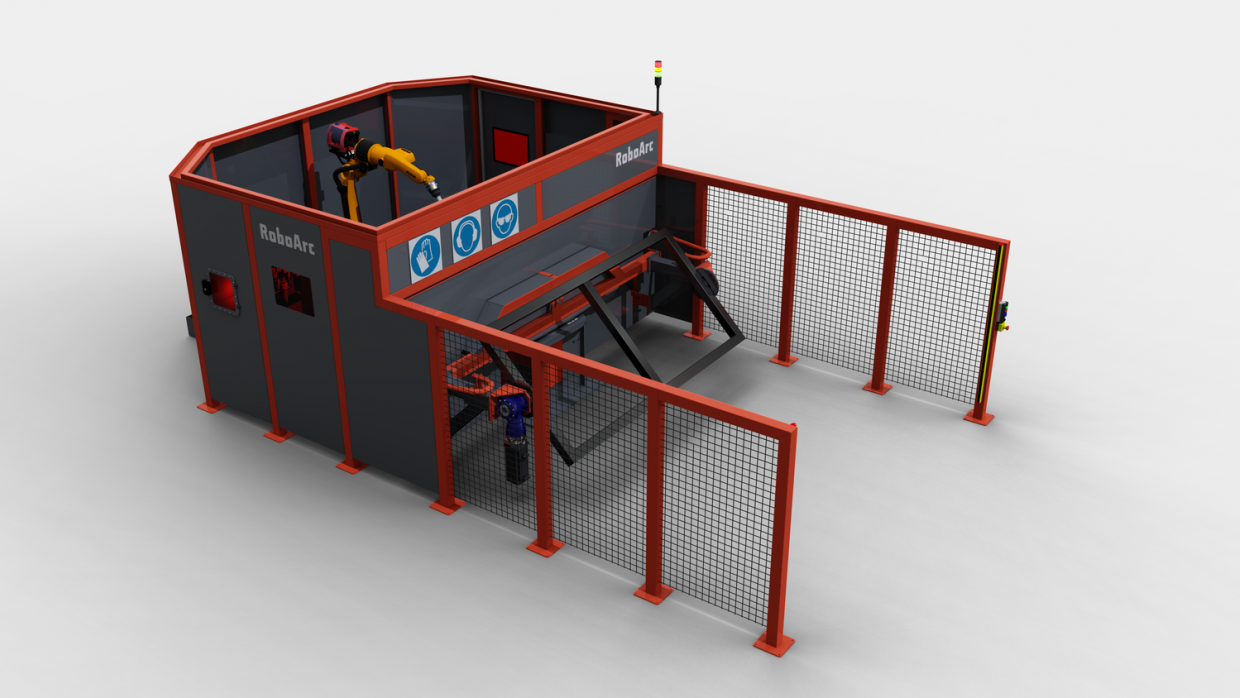

RoboArc_C

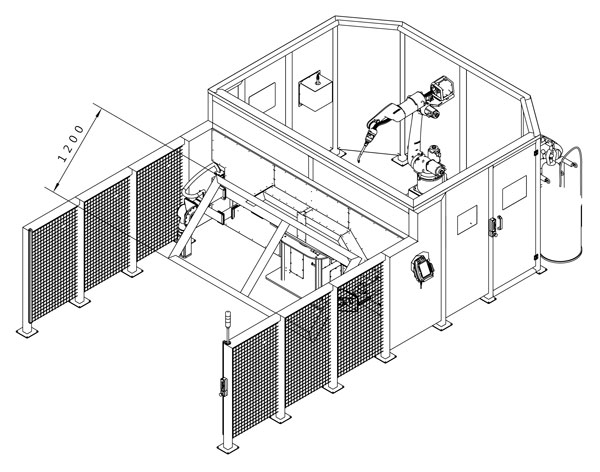

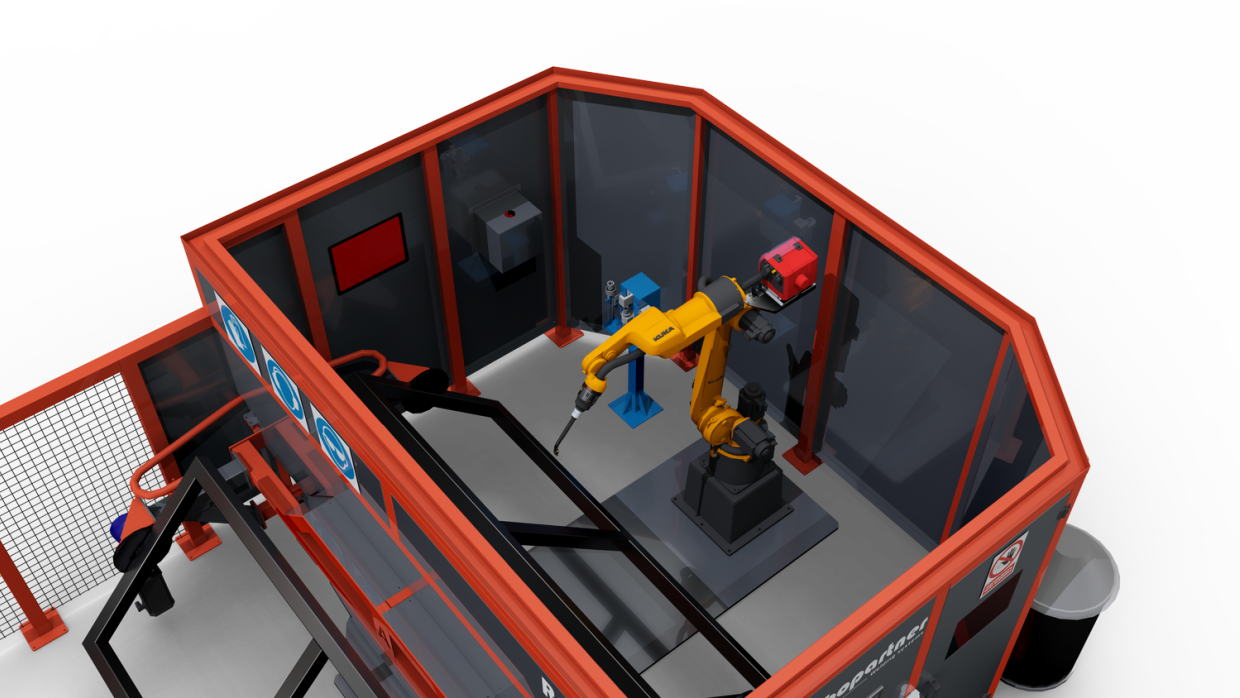

Welding Cell with H-Type Welding Positioner

Configuration![]() /

/

Available hardware configurations:

The robot is installed upright on a plinth, behind a H-type positioner comprising two processing zones: A and B, rotated alternately by 180° around the central axis. The design of the positioner enables single-axis rotation of the element being welded in each zone. Beams prepared for the assembly of positioning tools are mounted on the discs. The working area is equipped with an additional automatic welding torch cleaning station.

2-year

warranty

Comprehensive

start-up

Staff

training

Technical

Support

Benefits:

- Highly functional welding positioner

- Well thought-out solutions providing flexibility and operational reliability

- Fixed loading/unloading point

- Shared robot and positioner panel

- Compact design

- Fast delivery

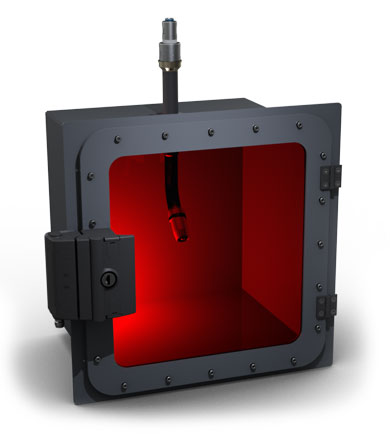

Selected additional options

Specifications

| Maximum robot reach: | 2 100 mm |

| Maximum positioner load: | 125 - 1000 kg |

| Maximum positioner capacity (per side): | 2500 x 1400 mm |

| Power supply: | 400V~ 3+PE 50 Hz |

| Rated power: | 44 kW |

| Supply pressure: | 6 bar |

| Cell dimensions (for the largest positioner): | 5000 x 4500 x 2500 mm |

| Cell weight: | 2 700 kg |

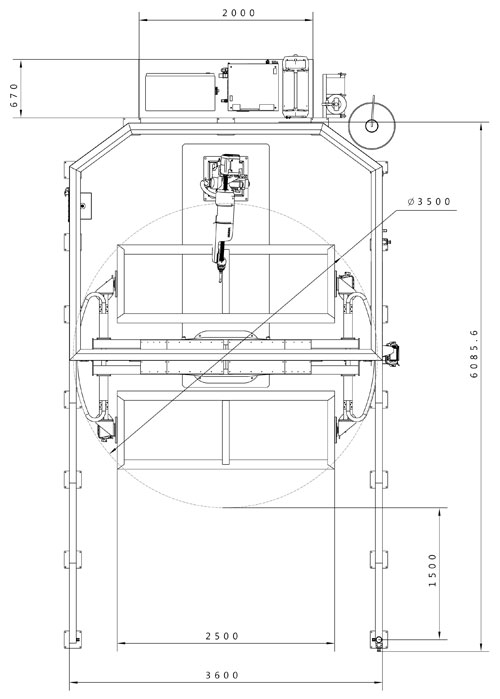

Dimensions

/

/

/

/

/

/